Quality Policy

“Customer satisfaction is our primary goal. Continuous process improvement through active participation of all employees is our thrust to achieve leadership in quality, price and delivery.”

Quality Management

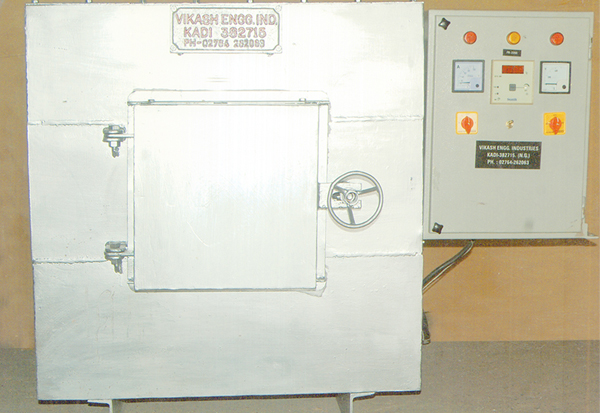

Vikash Engineering Industries is quite aware of the modern day global demands with respect to systems. It has an elaborate quality assurance system in place. However, today's demands are not just in terms of quality of products but relate also to back up and developmental services provided by a vendor.

In tune with this perception, Vikash Engineering Industries is well on its way to establish a quality system based upon the ISO 9000 series of standards. A department is presently in the process of being set up exclusively to look into the pecuniary needs of the company.

Quality Objectives

Vikash Engineering Industries aspires to provide its clients with a wide range of indigenously developed quality products for the Industries its serving - comparable to the best available alternatives in the world.

It aspires to continue with its Quality Control activities and fine tune the quality control processes specifically required by our standards.

In order to accomplish this, the Company has set the following objectives :

- Detect and prevent non - conformance during manufacturing & implement the means to prevent its re-occurrence.

- Upgrade technology and improve techniques, systems & procedures and to carry innovations to meet the customers’ changing needs.

- Develop highly motivated and skilled human resources imbued with a strong sense of values and commitment to quality.

- Create a healthy working environment for the employees.

- Discharge responsibilities to various sections of the society and preserve the environment

Inspection Facilities Provided at three stages :

- Inbound stage

- Processing stage

- Final stage

.jpg)

.jpg)