The company’s main line of activity is, research, development, manufacturing and marketing of non-conventional & renewable energy equipments, i.e. PRODUCER GAS PLANTS,FURNACE (OIL, GAS, ELECTRICITY BASED)& KILN-OIL & GAS.

is gas cheapest fuel and can substitute Furnace Oil, LDO, Kerosene, other fuel and other gases. It is ideally adopted to industrial heating operation, because of its uniformity, cleanliness and depend ability.

producer gas is generated by injecting a blast of air and steam through a layer of incandescent coal or coke.The carbon of the coal or cock combines with oxygen of the air to from carbon dioxide and the carbon dioxide as it goes up meets hot unburnt coal or cock in reduction zone to form carbon monoxide. The water vapors which passes through the fuel reacts to form carbon monoxide and hydrogen.

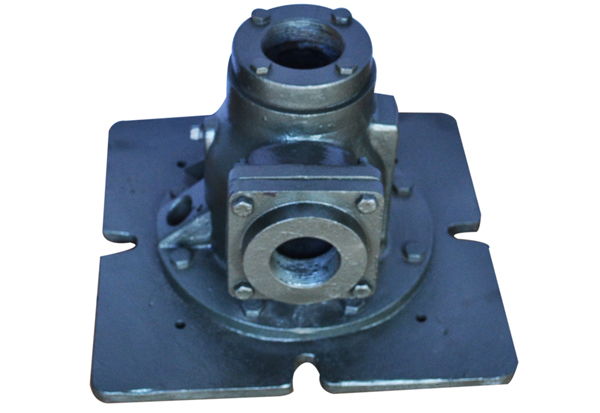

The chief combustible elements in producer Gas are carbon monoxide and some hydrocarbon. VEI Producer Gas Plant fabricated similar to Wellman Galusha Plant, U.S.A. with modification for better gasification higher out put has stepped rotary grate.

A two compartment fuel bin from the top of machine.

The upper section serve as a storage bin, fed by any suitable handling device for the fuel. The lower compartment is separated from the upper by gas tight gate through which fuel is fed as required.

The gas making chamber is completely water jacketed. The inner wall of thick heavy quality steel plate requires no brick lining. This not only eliminated the initial cost of such linings, but cuts maintenance cost as well as eliminating brick walls.

Clean dry gas ideal for use in ordinary burners and even hot gas can be used in Kiln furnaces hundreds of feet away without great loss in sensible heat. VEI gas burners in the same manner as either manufactured.

Producer gas can replace oil in any type of Kiln or Furnace or Chemical Plant, Steel Mills, Wire Mills, Ceramic Tunnel Kiln and Periodic Kiln, Refractory Kiln, Zinc Smelting, Carbide Kiln, Bakery, Tin, Plant Mills, Hot Air Generator & Boiler.

GASIFICATION (General)

Gasification is a major & unique element in the development of advance, improved, Renewable energy system. it is a thermo-chemical process that converts solid biomass coal/ bio-coal to a low heat value (LHV) gaseous fuel "Producer Gas". This Producer Gas is fuel for many different application of thermal power in the equipment like Furnaces, Kilns dryers, rolling mills and heat treatment equipment. Boiler, Hot air Generator.

The equipment to be utilized for gasification is known as a GASIFIER. On the basis of flow of gas in the reactor, gasifier is generally divided into two major groups like UPDRAFT and DOWNDRAFT Gasfire. An updraft Gasifire is more efficent & generally utilized for Thermal application.

FEATURE & ADVANTAGESS

The Bio-mass Gasifire system is capable of gasyfying several types of solid fuel such as Charcoal, Lignite, Imported Steam coal, Briquettes and high efficiency cock

Complete up-draft Gasifier system for your thermal application. Manufacturing Capacity 200 kw To 7500 kw (2 lakh K.cal / hr to 65 lac K.cal/hr)

| A | Steam Coal - B Grade | 3.00 kg / Liters Liquid Fuels |

| B | Steam Coal - C & D Grade | 3.50 kg / Liters Liquid Fuels |

| C | Steam Coal - Imported | 2.2 kg / Liters Liquid Fuels |

| D | Bio-Coal / Briquette | 3.50 kg / Liters Liquid Fuels |

| E | Charcoal | 1.75 kg / Liters Liquid Fuels |

| F | Lignite | 4.00 kg / Liters Liquid fuels |

| A | Slid Fuel Size | 20 mm to 60 mm |

| B | Moisture Content | 15 % |

| C | Ash Content | Up - to 25% |

| Charcol | Steam Coal (Imported) | Coke |

| Briquette/ Bio-Coal | Steam Coal (indian) | Lignite |

The Gasifier can convert any type of coal / Bio-Mass inTO Producer Gas. The chemical Compaction of Producer Gas is as under.

| CO ( Carbon Monoxide) | 22 @ 2% |

| CH4 (Methane) | 6 @ 1% |

| H2 (Hydrogen) | 18@ 2% |

| CO2 (Carbon Dixde) | 4 @ 2% |

| N2 (Nitroogen) | Rest |

| Calorific value | 1250 K.Cal / Hrs. |

| Out put Gas Temp. | 175 ºc to 250 ºc |

| Max. flame Temp. | 1450 ºc |

Contact No.

+91 (02764) 262063

Email Id

Info@gassifire.com nahata.br@rediffmail.com